Air Cooled Shaker

CATEGORIES

- (11) Vibration Testing System

- Miniature Shaker

- Air Cooled Shaker

- Water Cooled Shaker

- Slip Table

- Head Expander

- Multi-axis Shaker

- Climate Chamber Combined Shaker

- Vibration Controller

- VSA-D series Switching Power Amplifier

- MI-81 Series MISO Vibration Controller

- VT-9 Series Vibration Controller

- (5) Measurement and Analysis System

- (2) Transducer Calibration System

EDS/EDM series electro-dynamic shakers play an important role in environmental testing. It provides a testing platform for product vibration testing in cases of design and type test, packing and transportation, reliability mission profile, fatigue test and more real-world environmental simulation. These tests are widely needed among most of industries, from automotive to IT, from household electrical appliances to satellite, from civil to defence labs.

The working principle of electro-dynamic shaker is that the shaker armature is moved in a magnetic field under electromagnetic force, which is generated by the interaction between driving current and magnetic flux. Therefore, we can get a wide range of vibration force by changing the driving current, the larger driving current, the higher force.

ECON presents customers EDS/EDM series electro-dynamic shaker with years experiences and optimized design, which is a better choice for customers to conduct vibration tests.

Features

- Sine force range from 3kN to 50kN

- Rugged suspension system and linear motion guidance

- Double magnetic circuit design

- Auto-centering control integrated

- High reliability with mean time between failures(MTBF)> 10,000 hours

- More effective cooling structural design

- Optional foundation-free design available

- Optional Multi-shaker and Multi-axis design available

- Optional climate chamber combined shaker design available

|

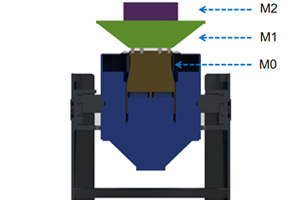

Calculation Formula of Excitation Force F=M*a=(M0+M1+M2+...)*a |

|

Shaker Model |

EDS-300 |

EDS-600 |

EDM-1000 |

EDM-2000 |

EDM-2200 |

EDM-3200 |

EDM-3200LT |

|---|---|---|---|---|---|---|---|

|

Rated Sine Force (kN/kgf) |

3/300 |

6/600 |

10/1,000 |

20/2,000 |

22/2,200 |

32/3,200 |

32/3,200 |

|

Shock Force (kN/kgf) |

6/600 |

12/1,200 |

20/2,000 |

40/4,000 |

44/4,400 |

64/6,400 |

64/6,400 |

|

Usable Frequency Range (Hz) |

5-4,000 |

5-3,500 |

5-3,000 |

5-3,000 |

5-3,000 |

5-2,500 |

5-2,500 |

| Max. Acceleration (m/s^2) | 981 | 981 | 981 | 981 | 981 | 981 | 981 |

|

Max. Velocity (m/s) |

2 |

2 |

2 |

2 |

2 |

2 |

2 |

|

Max. Displacement (mm) |

25.4 |

51 |

51 |

51 |

51 |

51 |

51 |

|

Max. Static Payload (kg) |

120 |

300 |

300 |

300 |

300 |

500 |

500 |

|

Armature Diameter (mm) |

150 |

200 |

240 |

320 |

320 |

320 |

370 |

|

Effective Moving Elements Mass (kg) |

3 |

6 |

10 |

20 |

20 |

32 |

32 |

|

Power Amplifier Model |

VSA-D402A |

VSA-D802A |

VSA-D123A |

VSA-D243A |

VSA-D243A |

VSA-D323A |

VSA-D323A |

|

Amplifier Type |

Switching |

Switching |

Switching |

Switching |

Switching |

Switching |

Switching |

|

Rated Power Output (kVA) |

4 |

8 |

12 |

24 |

24 |

32 |

32 |

|

Power Supply Requirement (kVA) |

7 |

16 |

26 |

40 |

40 |

65 |

65 |

|

Air Blower Model |

PBL-W03 |

PBL-W06 |

PBL-W10 |

PBL-W20 |

PBL-W20 |

PBL-W30 |

PBL-W30 |

|

Blower Power (kW) |

0.75 |

4 |

4 |

7.5 |

7.5 |

7.5 |

7.5 |

|

Air Flow (m^3/s) |

0.2 |

0.3 |

0.356 |

0.66 |

0.66 |

0.66 |

0.66 |

|

Air Pressure (kgf/cm2) |

0.015 |

0.048 |

0.058 |

0.075 |

0.075 |

0.06 |

0.06 |

|

Hose Diameter (mm) |

120 |

120 |

120 |

200 |

200 |

200 |

200 |

|

Shaker Model |

EDM-3200LS |

EDM-4000 |

EDM-5000 |

EDM-5000LS |

|---|---|---|---|---|

|

Rated Sine Force (kN/kgf) |

30/3,000 |

40/4,000 |

50/5,000 |

50/5,000 |

|

Shock Force (kN/kgf) |

60/6,000 |

80/8,000 |

100/10,000 |

100/10,000 |

|

Usable Frequency Range (Hz) |

5-2,500 |

5-2,500 |

5-2,500 |

5-2,500 |

|

Max. Acceleration (m/s^2) |

750 |

981 |

981 |

800 |

|

Max.Velocity (m/s) |

1.8 |

1.8 |

1.8 |

1.8 |

|

Max.Displacement (mm) |

100 |

51 |

51 |

100 |

|

Max. Static Payload (kg) |

500 |

800 |

1000 |

800 |

|

Armature Diameter (mm) |

350 |

445 |

445 |

445 |

|

Effective Moving Elements Mass (kg) |

40 |

40 |

50 |

63 |

|

Power Amplifier Model |

VSA-D323A |

VSA-D483A |

VSA-D563A |

VSA-D563A |

|

Amplifier Type |

Switching |

Switching |

Switching |

Switching |

|

Rated Power Output (kVA) |

32 |

48 |

56 |

56 |

|

Power Supply Requirement (kVA) |

65 |

80 |

90 |

90 |

|

Air Blower Model |

PBL-W30 |

PBL-W40 |

PBL-W50 |

PBL-W50 |

|

Blower Power (kW) |

7.5 |

22 |

22 |

22 |

|

Air Flow (m3/s) |

0.66 |

1.36 |

1.36 |

1.36 |

|

Air Pressure (kgf/cm2) |

0.06 |

0.09 |

0.09 |

0.09 |

|

Hose Diameter (mm) |

200 |

200 |

200 |

200 |