Optional

-

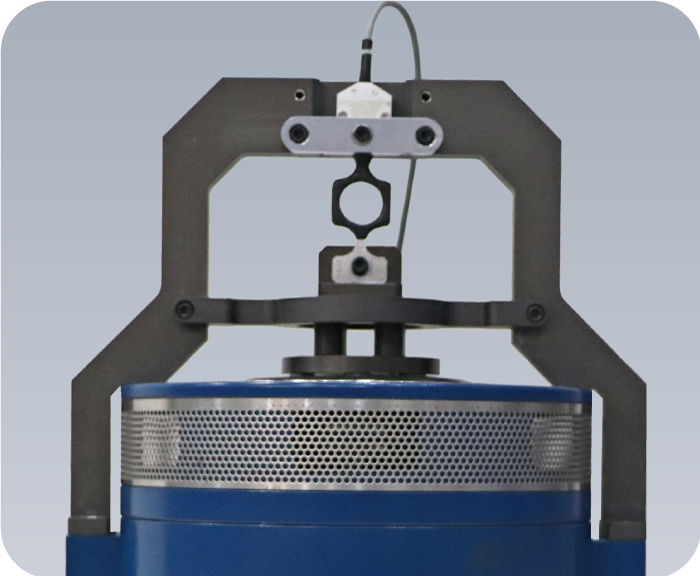

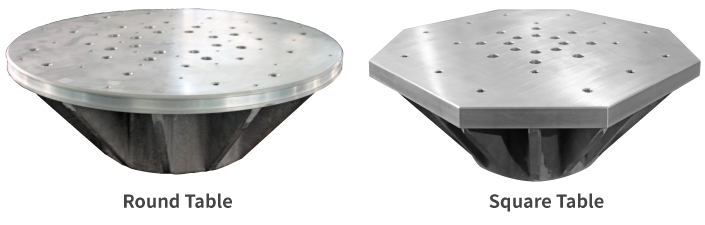

Head Expander

HE seriesA head expander can be added to larger test parts to expand electro-dynamic shaker coils. Made from lighter magnesium or aluminum alloy, it offers better strength-toweight ratio and frequency response characteristics.

-

Specifications

Model number vibration generator EDS-300 EDS-600 EDM-1000 EDM-2000 EDM-3200 EDM-5000 mounting screw hole M8 M8 M10 M10 M10 M12 Round shape

HE-300RA ◎ ◎ HE-400RA ◎ ◎ ◎ HE-500RA ◎ ◎ ◎ ◎ ◎ HE-600RA ◎ ◎ ◎ ◎ ◎ HE-800RA ◎ ◎ ◎ HE-1000RA ◎ HE-1200RA ◎ square shape

HE-300SA ◎ ◎ HE-400SA ◎ ◎ ◎ HE-500SA ◎ ◎ ◎ ◎ ◎ ◎ HE-600SA ◎ ◎ ◎ ◎ ◎ ◎ HE-800SA ◎ ◎ ◎ ◎ HE-1000SA ◎ ◎ HE-1200SA ◎

Optional

-

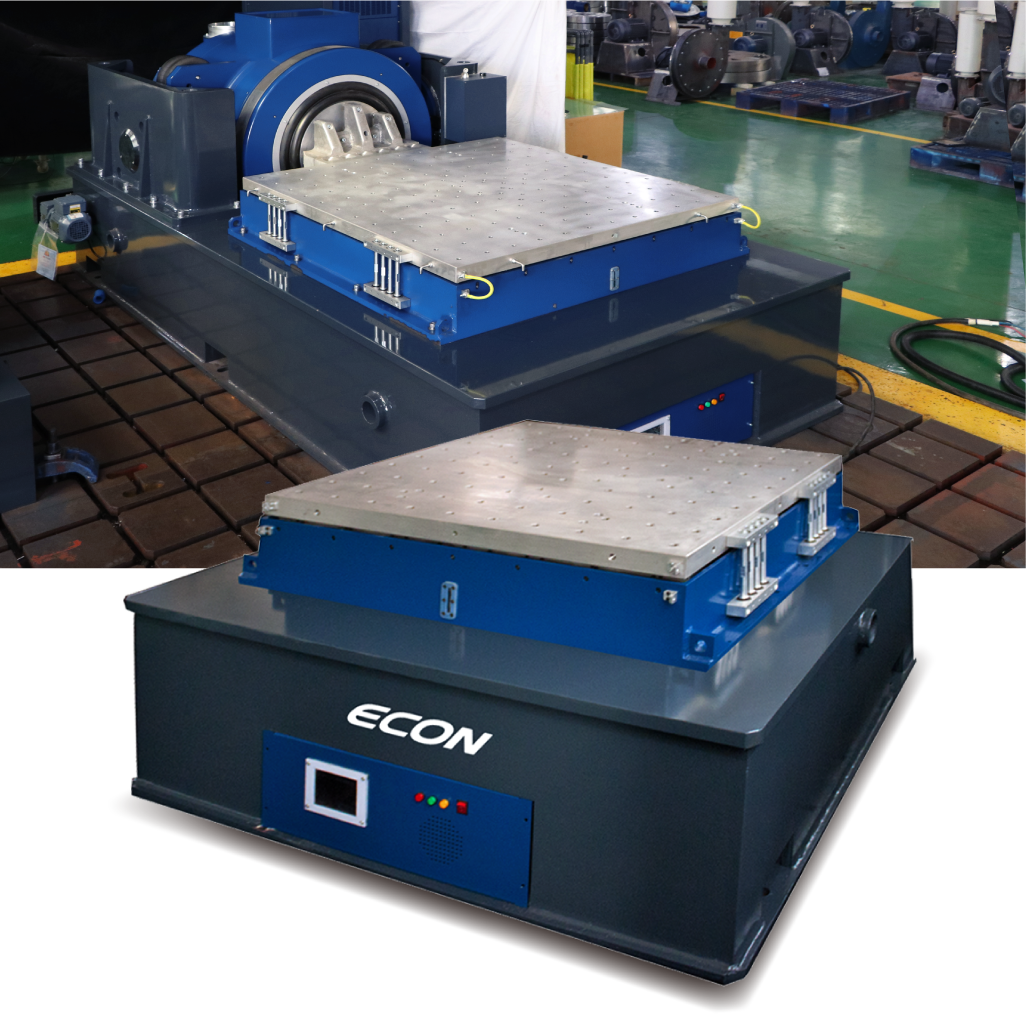

Slip Table

ST seriesAn auxiliary slip table can expand the size of test parts in electro-dynamic shakers, increasing installation area. Made from lighter magnesium or aluminum alloy, it offers better strength-to-weight ratio and frequency response characteristics.

-

Features

・ High-quaility aerospace class Material ;

・ Usable frequnency range up to 2,000Hz ;

・ Metirc and English units optional ;

・ Magnesium or Aluminum optional ;

・ Various insert mounting hole patterns available ;

・ Corrosion resistant:non-machined parts are paintes; machined parts are coated with lubricant ;

・ Customization for special requirements ;

-

Specifications

Compatible vibration generator Horizontal auxiliary table model number Table size (mm) Thickness (mm) Moving part mass (kg) Maximum load (kg) Usage frequency (Hz) EDS-300 03ST-300M 300×300 twenty five 8.5 100 2000 03ST-400M 400×400 11.5 150 03ST-500M 500×500 17 150 EDS-600 06ST-400M 400×400 twenty five 14 150 2000 06ST-500M 500×500 40 26.5 300 06ST-600M 600×600 35 300 EDM-1000 10ST-400M 400×400 twenty five 15 150 2000 10ST-500M 500×500 40 28 300 10ST-600M 600×600 38 300 10ST-800M 800×800 57 400 EDM-2000 20ST-500M 500×500 40 29 300 2000 20ST-600M 600×600 38 300 20ST-800M 800×800 50 72 400 20ST-1000M 1000×1000 107 500 EDM-3200 30ST-500M 500×500 40 29 300 2000 30ST-600M 600×600 38 300 30ST-800M 800×800 50 72 400 30ST-1000M 1000×1000 107 500 EDM-5000 50ST-500M 500×500 40 38 300 2000 50ST-600M 600×600 46 300 50ST-800M 800×800 50 85 400 50ST-1000M 1000×1000 120 500 50ST-1200M 1200×1200 167 500

Option

-

Automatic Centering Controller (ACC)

The automatic centering controller uses a non-contact sensor to detect the center position of the vibration generator's moving coil. The static centering feature ensures that the vibration generator is centered by adjusting the center airbag of the moving coil. During loading and unloading of the specimen, the centering device automatically expands and contracts so that the moving coil is always at the center of the stroke. The dynamic centering feature can maintain the center position of the table during movement, so the positive and negative amplitudes are always symmetrical to the center position when the slip plate is moving.

Features

-

- Simple operation and ease of use.

- An emergency stop switch is linked to the system, making it safe and reliable.

- Static automatic adjustment of center position.

- Dynamically maintains the center position of the moving part coil.

Option

-

Auxiliary Stay Bearing

Whether a lateral load reinforcement guide mechanism is required for the auxiliary table depends on the weight and eccentric load of the specimen. ECON offers a variety of auxiliary stay bearing and a variety of guide mechanisms. Equipped with a lateral load reinforcement guide mechanism, the maximum loadable mass and allowable eccentric moment of the device are greatly improved, making it possible to handle specimens with a high center of gravity, specimens whose center position is shifted, and specimens of various shapes. It is possible to load heavy specimens. Therefore, tests under harsh transportation conditions can be effectively simulated and tested under more severe test conditions. Option

Option

-

Air Spring Isolator (ASI)

The anti-vibration air spring base (bottom suspension method) can be used when it is inconvenient or difficult to build the foundation base at the customer's site. High-quality air springs are used to elastically support the vibration test equipment and reduce the excitation of the vibration equipment to the ground. The bottom suspension system has a high vibration isolation effect for vibration frequencies exceeding 10Hz.

Option

-

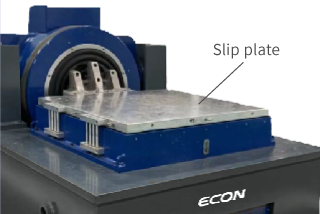

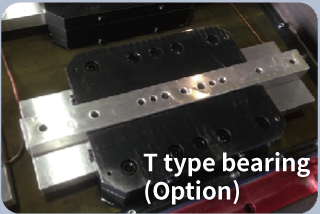

T Guide Bearing

The guide bearing is located below the slip plate, which can make the slip table move accurately and smoothly.

A V-guide bearing is installed as standard. It is a high-cost performance type with a lightweight and simple structure and a built-in low-pressure oil source, but an optional T-guide bearing can be selected for tests with large loads and overturning moments. T-guide bearings have an external medium-pressure oil source, a higher anti-overturn moment, and are ideal when the test load is large and the center of gravity is high.

Option

-

Assembly Fixture

Fixture can assist customers in fixing different Test targets on the shaker to complete Test.

Fixtures can be customized according to customer needs.