Customized Multi-/Multi-axis shaker

2EDS/3EDS series-

Realistic reproduction of vibration test results under complex conditions

ECON supply multi-axial/multi-DOF vibration system, such as bi-axial shaker and tri-axial shaker, which can reproduce more realistic vibration conditions than traditional uniaxial shaker.

It could hightly reduce the rate of over test or lack of test during complex tests. In addition, test results with multiaxial shaker will be more reliable as well as the test duration can be greatly reduced compared with the traditional tests with uniaxial shaker.

-

Features

・ Customized design of multi-axis,bi-axial/triaxial synchronized ;

・ Optional of reliable motion trail and hydraulic orthogonal decoupling bearings ;

・ Foundation-free design optional ;

・ Advanced MIMO vibration controller with accurate system

・ Random frequncy range up to 2,000Hz ;

・ identification and highly adaptive matrix control ;

・ Max. 16 drive outputs

Applications

Aviation & Aerospace

When a single test reaches a large set test level for a long strip or beam-like specimen, such as a missile, the local stress on the contact surface of the specimen and the fixture is too great, resulting in local failure damage.

Civil & Structural Earthquake Resistant

Seismic simulation tests in the field of civil engineering, whose vibrations cannot be decomposed through the axial direction, must be conducted simultaneously in two or more positions of excitation.

Vehicle & Road Spectrum Simulation

System-level tests in the automotive field, such as road spectrum simulations, with multiple unidirectional simulations are increasingly different from the actual multidimensional vibration environment, affecting the quantitative assessment of the reliability of the tested products.

Mechanical Equipment

Large test pieces of mechanical equipment, the vibration of a single position can not guarantee the uniformity of vibration, the response of different positions on the test piece has a large difference, and the distribution of stress and displacement is unreasonable.

-

Specifications

System Model 2EDS-600-XY 3EDM-1000 2EDM-5000-XY Sine Force Peak (kN) 5.88 9.8 49.1 Frequency Range (random) (Hz) 2000 2000 2000 Max. load (kg) 200 200 800 Max. Displacement (mm) 38 38 38 Max. Velocity (m/s) 1 1 1 Max. Acceleration (m/s²) 150 196 295 Effective armeture mass (kg) 40 50 165

-

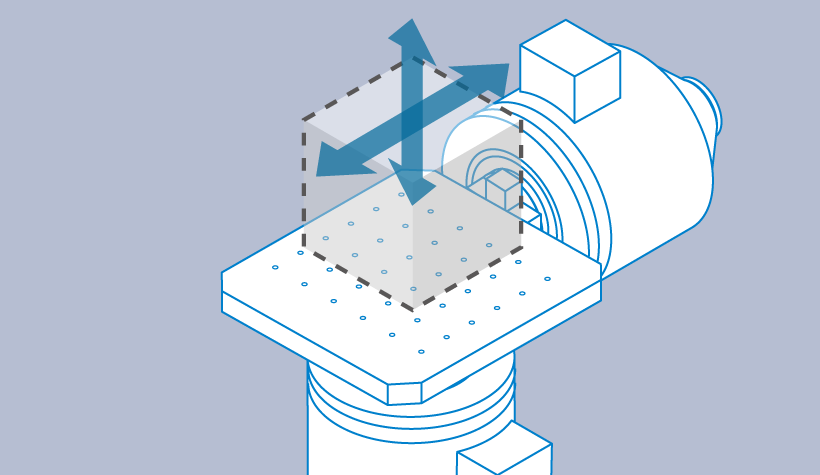

Bi-Axial Shaker

2DS/EDM series

-

-

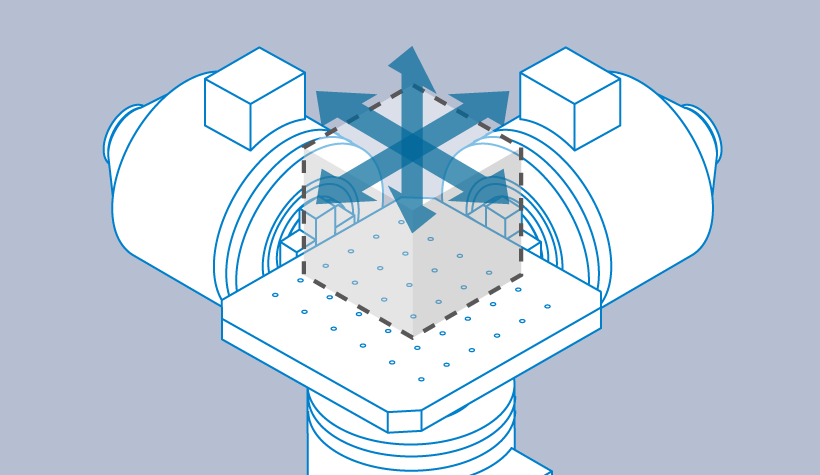

Tri-Axial Shaker

3DS/EDM series

-

-

Compatible vibration controller

High Channel Count Vibration Controller

MI-8008/8018

-

Compatible amplifier

VSA-H series Power Amplifier

VSA-H series